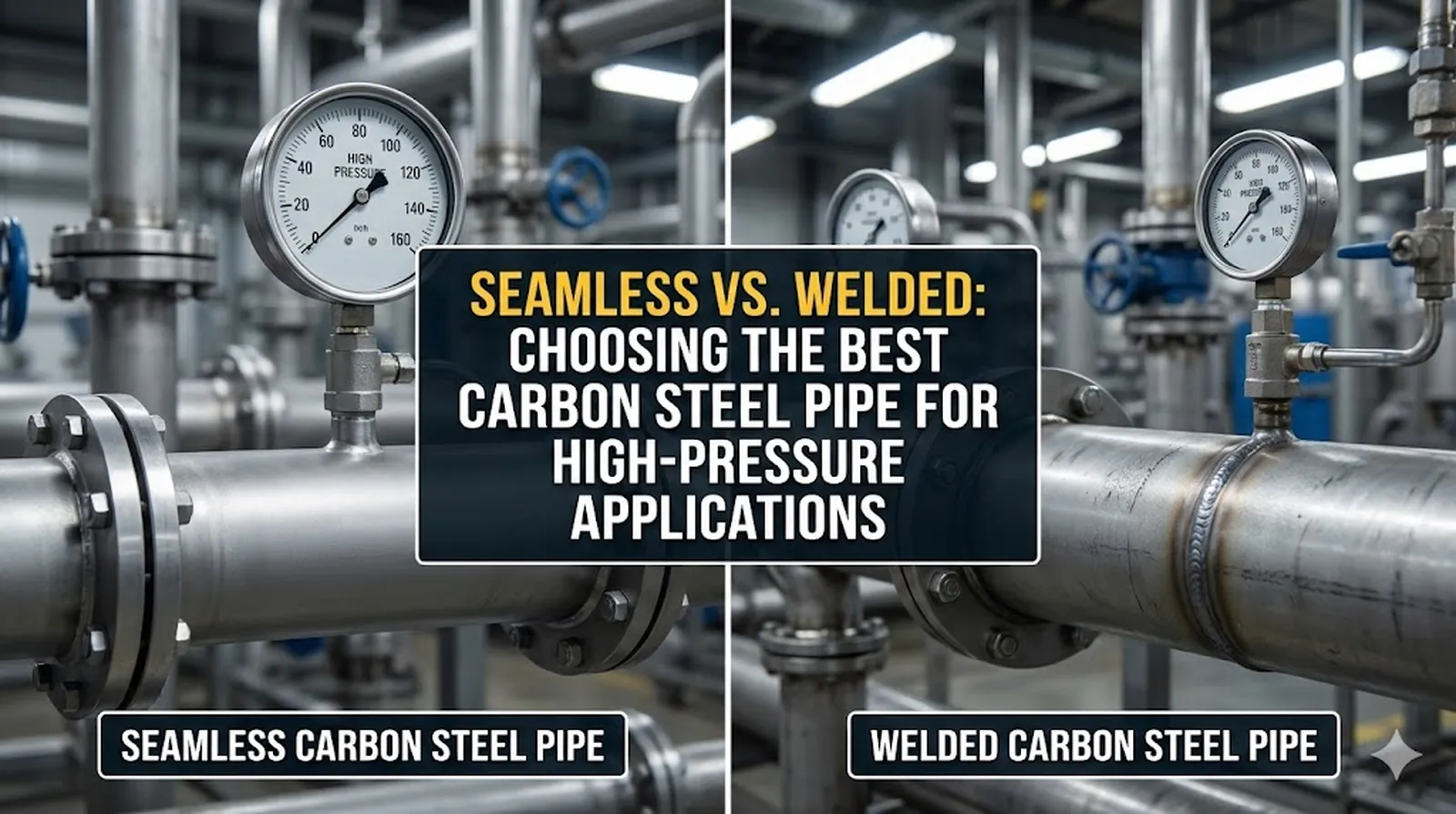

Seamless vs. Welded: Choosing the Best Carbon Steel Pipe for High-Pressure Applications

In critical industries like oil and gas, power generation, chemical processing, and infrastructure, the pipes used to transport fluids and gases are the lifeblood of the operation. When the stakes are high—involving high temperatures, flammable contents, and extreme pressures—the integrity of the piping material is non-negotiable.

For carbon steel pipe, the foundational choice that determines performance, safety, and cost is the manufacturing method: **Seamless Pipe** or **Welded Pipe**. This decision is especially critical when the pipe is intended for **high-pressure applications**.

This comprehensive guide breaks down the core differences between seamless and welded carbon steel pipe. We will examine their production, their inherent strengths and weaknesses, and provide clear criteria for selecting the safer, more reliable option for your demanding high-pressure project.

💎 Deep Dive: Understanding Seamless Carbon Steel Pipe

What is Seamless Pipe?

Seamless pipe is exactly what the name suggests: a pipe with no seam, weld joint, or fusion point anywhere along its length. It is a single, continuous piece of metal from end to end.

How is Seamless Pipe Made?

Seamless pipe begins as a solid, cylindrical piece of steel called a **billet** or **round bar**. The production process involves:

- Heating: The solid billet is heated to extremely high temperatures.

- Piercing: A rotating piercing tool is driven down the center of the hot billet. This process pushes the metal outward, creating a hollow tube (the pipe).

- Rolling: The pipe is then rolled and drawn to achieve the precise final diameter and wall thickness required.

Because the pipe is created from a solid block of steel, it retains a uniform crystalline structure throughout its entire circumference.

Key Characteristics for High-Pressure Use

- Structural Integrity: The uniform structure means there are no inherent weak points or stress concentrations.

- Pressure Rating: Seamless pipes have a significantly higher rated burst pressure than welded pipes of the same size and wall thickness. This is the single most important factor for high-pressure systems.

- Thickness and Size: Generally available in a wide range of wall thicknesses, perfect for heavy-wall requirements in power plants and deep-well applications.

Pros for High Pressure: Superior strength, uniform structure, high burst pressure rating, excellent reliability under mechanical stress and extreme temperatures.

Cons: Higher cost, longer lead times, usually only available in smaller diameters (typically under 24 inches).

🔗 Deep Dive: Understanding Welded Carbon Steel Pipe

What is Welded Pipe?

Welded pipe is manufactured by taking flat steel material—either plate or coil—and rolling it into a cylindrical shape. The edges are then fused together along the pipe’s length to form a longitudinal seam.

How is Welded Pipe Made?

The two main methods used for carbon steel pipe are:

- ERW (Electric Resistance Welding): This method uses an electrical current to heat the edges of the steel strip as they are forced together, creating a metallurgical bond without filler metal. It is common for smaller diameter, thinner-wall pipes.

- SAW (Submerged Arc Welding) or LSAW (Longitudinal SAW): Used for larger, thicker pipes. Filler metal is added to the seam, resulting in a highly visible weld.

Key Characteristics for General Use

- Cost and Availability: Welded pipes are cheaper and much faster to produce, making them the default choice for general, non-critical applications.

- Size Range: Welded pipes can be produced in virtually any size, making them essential for massive transmission lines (e.g., $48$ inches in diameter).

- Tolerance: Due to starting with flat sheet or coil, welded pipes usually have tighter dimensional tolerances (more precise wall thickness and diameter) than seamless pipes.

Pros for General Use: Lower cost, rapid production, excellent availability in large diameters, tighter wall thickness tolerances.

Cons for High Pressure: The weld seam is an inherent point of weakness, requires extensive non-destructive testing (NDT), and may suffer from weld defects under high stress.

🔬 The Critical Factor: Why Pressure Changes Everything

When pipe is subjected to high internal pressure, the primary forces acting on the material are **hoop stress** (stress around the pipe’s circumference) and **longitudinal stress** (stress along the length).

The Weakness of the Weld Seam

In a welded pipe, the weld seam is subjected to the same intense hoop stress as the rest of the pipe wall. Even in high-quality welding, the metal within the weld and the surrounding **Heat-Affected Zone (HAZ)** has a different chemical structure and mechanical property than the base metal.

Under sustained high pressure, this microscopic difference creates a point of stress concentration. If there are any flaws (porosity, incomplete fusion, lack of penetration), the pipe is highly susceptible to failure at the seam, leading to leaks or catastrophic bursts.

The Reliability of Seamless Pipe

Because seamless pipe lacks this inherent discontinuity, the stress is distributed uniformly across the entire pipe body. This symmetry allows the pipe to safely contain much higher pressures and withstand greater stress cycling (repeated pressure increases and decreases) over a long operating life.

This superior reliability is why the most stringent industry codes (like ASME B31.1 for Power Piping and ASME B31.3 for Process Piping) often mandate the use of seamless pipe for the most critical high-pressure, high-temperature lines.

✅ Selection Guide: When to Choose Which

Mandatory Seamless Pipe Applications:

Choose Seamless Pipe when: Failure is Catastrophic or Costs are Extreme.

- Pressure/Temperature Rating: Any application requiring the highest pressure ratings (e.g., above 1,000 psi) or involving high-temperature steam or chemical reactants.

- Safety and Environment: Transporting toxic, highly corrosive, or flammable contents where a leak poses a major risk (e.g., deep-sea pipelines, sour gas).

- Stress: Lines subjected to high mechanical loads, bending, or extreme thermal cycling.

- Industry Codes: When codes like API 5L, ASME B31.1, or B31.3 specifically require or strongly recommend seamless construction for the fluid and operating condition.

Acceptable Welded Pipe Applications:

Choose Welded Pipe when: Pressure is Moderate and Cost is Primary.

- Low/Moderate Pressure: Systems with working pressures under 500 psi, such as low-pressure steam, municipal water lines, or vent lines.

- Large Diameter: Projects requiring very large diameters (over 24 inches) where seamless pipe is either unavailable or prohibitively expensive.

- Structural Use: Piping used for structural supports, casings, or pile driving, where containment integrity is not the main concern.

Final Takeaway

The choice between seamless and welded carbon steel pipe boils down to prioritizing either ultimate safety and performance or lower initial cost.

For **high-pressure applications**, the initial premium paid for **Seamless Pipe** is a necessary investment in safety and operational continuity. Its lack of a weld seam eliminates the most common point of failure, making it the globally accepted standard for critical service lines.

Welded pipe serves an important role in general industry, but its use must be strictly limited to low-stress, non-critical environments to ensure long-term integrity.

To ensure your piping meets all necessary safety and code requirements, consult with our materials experts who can help you verify the pressure capacity and structural suitability of both seamless and welded carbon steel options for your specific project.