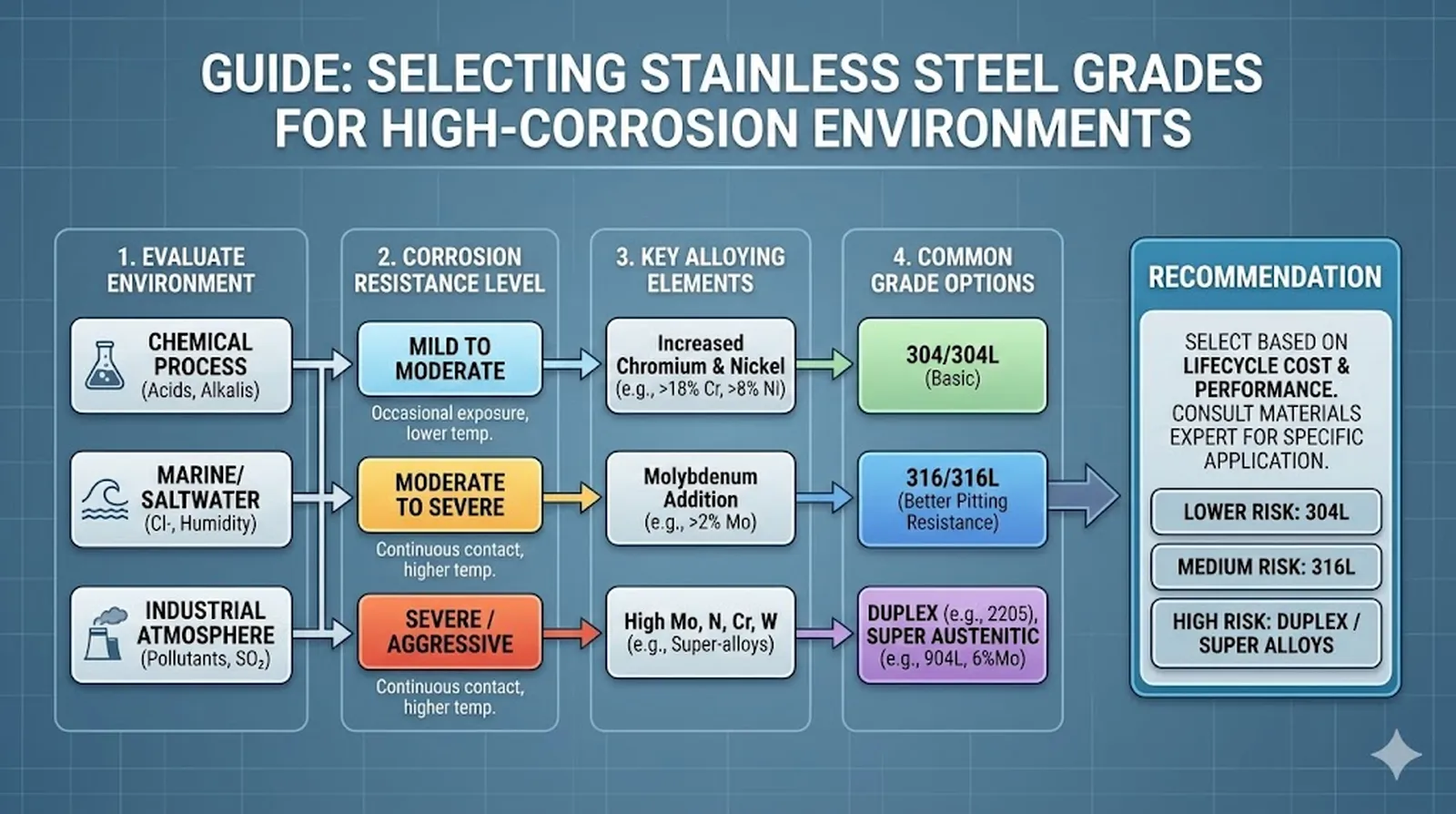

Guide to Selecting the Right Stainless Steel Grade for High-Corrosion Environments

Choosing the right material is the single most important decision in any industrial or construction project. When that project involves harsh chemicals, salty air, extreme temperatures, or continuous moisture, the margin for error is zero. In these demanding conditions, stainless steel is often the metal of choice.

However, stainless steel is not a single product; it is a family of hundreds of different metal alloys. Selecting an ordinary grade, such as the common 304, for a high-corrosion environment—like a chemical processing plant or a coastal offshore rig—can lead to catastrophic and expensive failures, often within a few years.

This guide provides a straightforward, technical understanding of what makes certain stainless steel grades resistant to the most aggressive forms of corrosion, and how to select the precise grade that guarantees long-term success and safety in high-corrosion environments.

Stainless Steel 101: The Magic of Chromium

What makes stainless steel “stainless” is a minimum of 10.5% chromium. This chromium is the key to corrosion resistance. When the steel is exposed to oxygen—even the small amount in air—the chromium instantly forms an ultra-thin, invisible layer of chromium oxide on the surface.

This layer is called the passive film. It is non-porous and self-healing. If the steel is scratched or damaged, the passive film reforms immediately, preventing rust (iron oxide) from forming underneath.

In a mild environment, the passive film of a standard grade like 304 is often enough. But in a high-corrosion environment, the passive film can be chemically attacked, broken down, or overwhelmed, leading to rapid and localized failure.

Understanding the Enemy: Types of Corrosion

Corrosion is complex, but in stainless steel, failure often occurs in specific, aggressive ways that the passive film cannot handle alone. Successful grade selection requires identifying the type of corrosion you are fighting:

1. Pitting Corrosion

This is the most common and dangerous failure mode. It happens when chloride ions (from seawater or salt) break through the passive film, creating small, deep pits. These pits quickly tunnel down into the metal, often leading to sudden failure without much surface warning. Pitting is a primary concern in marine and harsh chemical settings.

2. Crevice Corrosion

Crevice corrosion is similar to pitting but occurs in very tight gaps or shielded areas where oxygen is restricted (e.g., under bolt heads or flanges). Because oxygen can’t easily reach the metal in these crevices, the passive film cannot effectively self-heal, and the trapped chemicals become highly aggressive.

3. General (Uniform) Corrosion

This is the overall, evenly spread loss of material across the entire surface. It occurs when stainless steel is exposed to strong acids. The entire passive layer is dissolved, and the steel loses thickness quickly.

4. Stress Corrosion Cracking (SCC)

This is a brittle failure that occurs when three conditions are met simultaneously: corrosive media (usually chlorides), tensile stress (the material being pulled apart), and elevated temperatures (typically above $60^\circ\text{C}$). SCC creates microscopic cracks that spread rapidly, causing sudden failure.

The High-Performance Families: Your Best Options

1. The Workhorse: Austenitic Steels (300 Series)

| Grade | Key Elements | Corrosion Profile |

|---|---|---|

| 304 / 304L | 18% Cr, 8% Ni | NOT SUITABLE for high-corrosion environments. Fails easily due to pitting. |

| 316 / 316L | 17% Cr, 10% Ni, 2.0-3.0% Mo | Minimum Grade for chloride environments. Molybdenum is critical. |

| 317L | 18% Cr, 11% Ni, 3.0-4.0% Mo | Better resistance than 316L due to higher Molybdenum. |

2. The Superheroes: Superaustenitic Steels (6-Moly Grades)

These grades maximize Molybdenum, often reaching 6% or more. They are designed for severe environments, specifically where temperatures are high and the concentration of chlorides is extreme, such as deep-sea oil and gas applications. Key grades include **254SMO** and **AL-6XN**.

3. The Power Couple: Duplex Stainless Steels

Duplex steels are a balanced mix of Ferrite (high strength) and Austenite (high corrosion resistance). This hybrid structure offers a massive advantage: they have twice the strength of 316L and are highly resistant to Stress Corrosion Cracking (SCC).

- Standard Duplex (2205): Excellent all-around performer.

- Super Duplex (2507): Used in offshore platforms, subsea pipelines, and large, highly stressed pressure vessels exposed to high chlorides.

The Key Metric: Pitting Resistance Equivalent Number (PREN)

You do not need to memorize every steel’s chemical composition. Instead, use one number to compare their resistance to pitting: the Pitting Resistance Equivalent Number (PREN).

The PREN value is a calculation based on the percentage of the three key elements: Chromium, Molybdenum, and Nitrogen.

The rule is simple: the higher the PREN, the better the resistance to pitting and crevice corrosion. A PREN value of **32 or higher** is generally considered the threshold for high-performance steel that can handle warm seawater without severe pitting.

| Grade | Approximate PREN | Typical Use Environment |

|---|---|---|

| 304 | 18 | Indoor, mild moisture |

| 316L | 25 | Coastline, brackish water (minimum for marine) |

| Super Duplex 2507 | 43 | Offshore rigs, highly corrosive acids, pressure vessels |

The Selection Guide: Matching Grade to Application

1. Marine & Saltwater Environments

- Coastal (Piers): 316L is the minimum requirement.

- Subsea / High-Temperature Seawater: Use 2205 Duplex or 254SMO Superaustenitic (PREN $35+$).

- Offshore Rigs (Highly Stressed): 2507 Super Duplex is ideal for its strength and corrosion resistance.

2. Chemical Processing & Acid Tanks

- Dilute Acids: High-Molybdenum Austenitics like 317L are often adequate.

- Highly Corrosive Mixtures: **Superaustenitics (254SMO)** are a common solution for extreme chemical environments.

3. High-Temperature Environments (with Chlorides)

- Any system operating above $60^\circ\text{C}$ ($140^\circ\text{F}$) must consider **Stress Corrosion Cracking (SCC)**.

- Solution: **Duplex (2205)** steels are the preferred choice over standard Austenitic grades because their structure inherently provides far greater resistance to SCC.

Final Takeaway

Selecting the right stainless steel is a process of matching the material’s chemical defense to the environment’s specific attack.

- Identify the Threat: Is it primarily chloride (pitting), high heat (SCC), or strong acid (general corrosion)?

- Check the PREN: Aim for PREN 32+ for truly severe environments.

- Balance Strength and Resistance: If high mechanical strength is required, **Duplex** grades are often the most effective solution.

Do not settle for the cheapest or most common grade. A few extra dollars spent on a higher-grade stainless steel will save hundreds of thousands in repair, replacement, and downtime over the lifespan of your critical infrastructure.